What Methods Are Used to Remove Cranes from Construction Sites?

Depending on the crane and the job location, there are different ways to remove a crane from a construction site. Due to their considerable weight, cranes typically need to be moved by truck. Large cranes, including tower cranes, frequently need to be dismantled by smaller cranes because they are unable to do so on their own. The crane’s components will subsequently be loaded onto a truck and driven to their next destination.

However, crane removal techniques for mini cranes, which lift 10 tonnes or less, can differ because of their adaptability and frequent application in a variety of unconventional tasks.

How Do Mini Cranes Leave Construction Sites?

A strategy for securely navigating the crane in and out of a construction site is developed before the crane is even transported there. A lift plan cannot be built around an inoperable crane if there is no way to get the crane in or out.

Trucks for Removing Mini Cranes

This is one of the more typical methods for removing micro cranes from a building site. You can easily use the controls or remote to just drive the crane across the construction site and up a ramp into a waiting vehicle because tiny cranes are frequently movable.

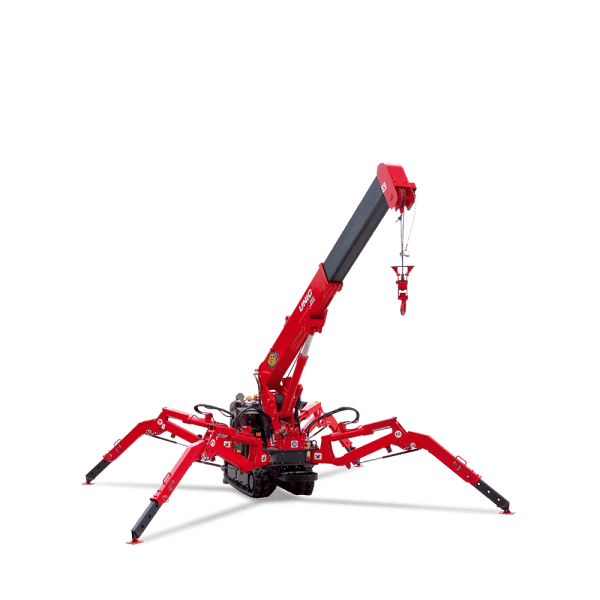

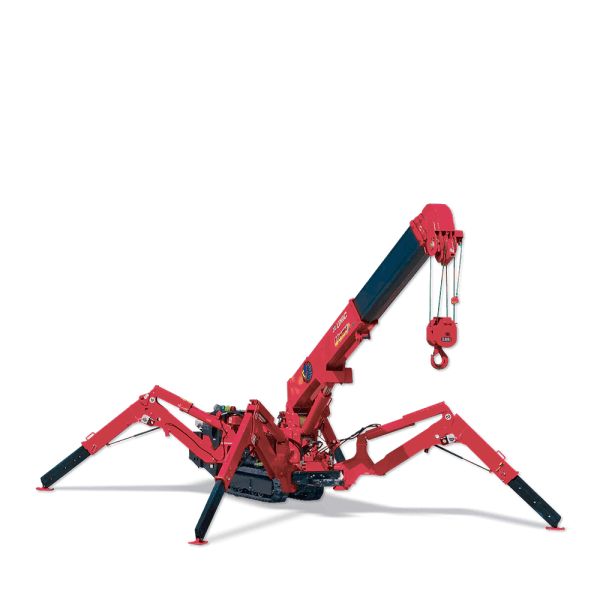

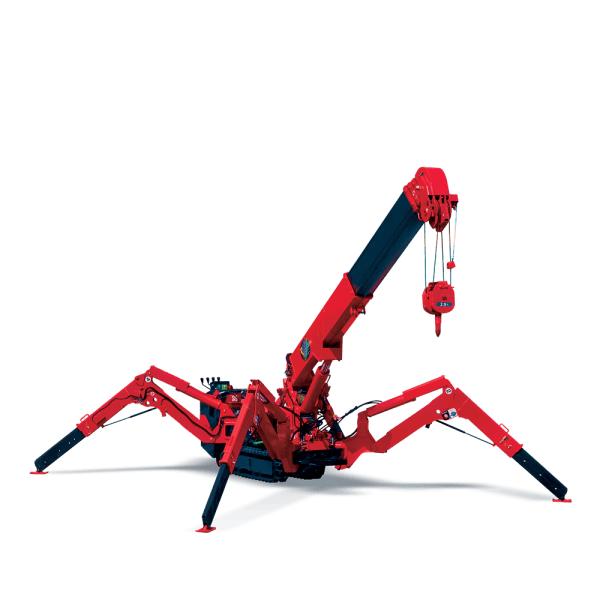

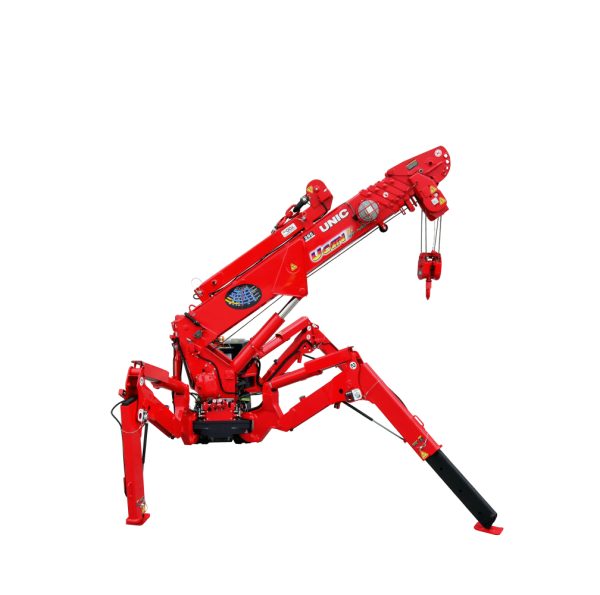

Some cranes, like the Pick and Carry Crane, can be placed into a vehicle in their current state. However, in order to move a crane with outriggers safely, such as a Mini Spider Crane, you must first retract the outriggers. This is because it’s risky to leave the outriggers out because they can hit people or things. The crane can be made as small by retracting the outriggers, allowing for safer transit through crowded work sites.

We show you in this video how easy it is to store your outriggers. The crane can now be easily loaded onto a truck and transported to its next work after being stored.

Take Your Crane Apart

Mini cranes occasionally need to be disassembled in order to leave a building site. Restricted access is frequently the source of this. Because tiny cranes are so little, disassembling them is frequently simpler than disassembling a tower crane. Other cranes can readily move these lightweight components to the required location for the crane.

Our cranes have been used in several projects like this as a lifting solutions provider with over 25 years of experience. Strength is often needed for these occupations, but there may be accessibility issues. We generally send a Mini Spider Crane for situations like these because of its amazing compactness and lifting capacity.

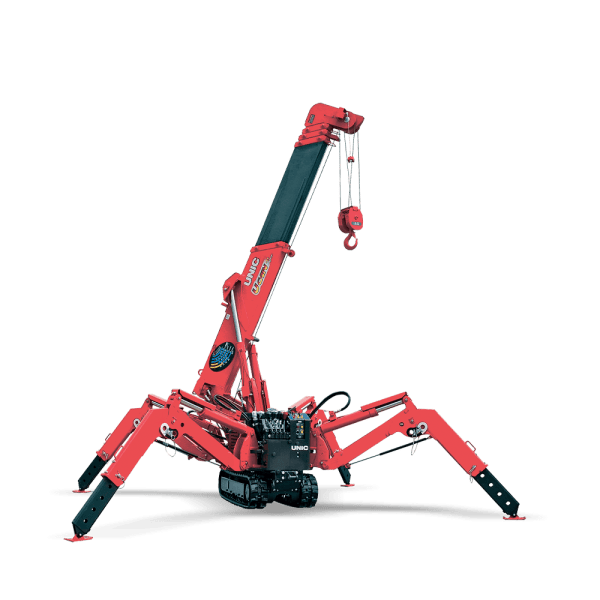

The decommissioning of the primary containment within the Steam Generating Heavy Water Reactor was accomplished using our 706, which was purchased by a nuclear site management firm. The 706 was split into two pieces and slid down a nuclear site building many floors. These steps were then conducted backwards to remove the crane.

Not all miniature cranes can be taken apart, though. If in doubt, always contact the manufacturer.

Remove It Using a Crane

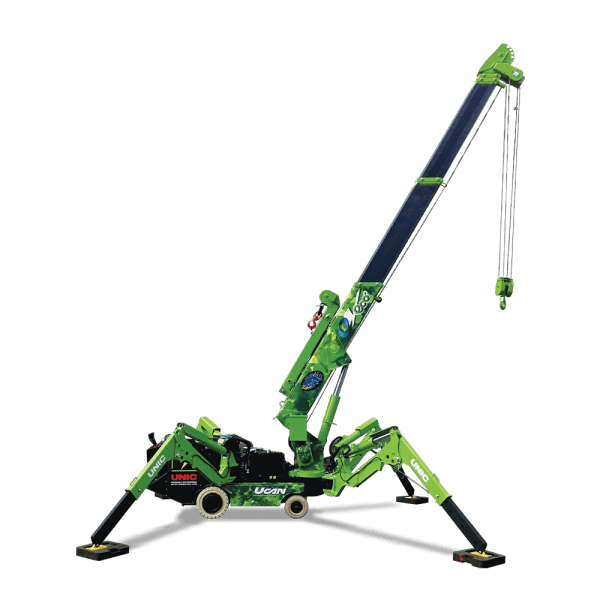

Due to their frequent use in places with limited access, cranes are frequently only able to be removed from construction sites by other cranes. This is due to the fact that tiny cranes can lift objects that larger machines cannot. They might be hoisted onto a roof, lowered through many stories, or flown to a hilltop by helicopter.

Mini cranes are frequently employed in these settings due to their compact size and light weight. They can therefore be used on roofs because they won’t likely weigh more than the roof can support. Additionally, they are more economical, particularly when lifting the crane’s component parts by helicopter. They are ideal for sporadic and unique jobs since they use less fuel and require fewer operators.

One of our most noteworthy tasks featured the crane-lifting of a 706. To add an extra helping hook, the URW-706 Mini Spider Crane was dispatched to the top of The Shard. The 706 installed 440 glass panels for 11 weeks. The project was able to be finished in time for the 2012 Olympic Games thanks to the employment of the additional crane. The 706 was then split in two and removed by crane before being transported back to the Haddenham depot via van.

Due to their special features and small size, mini cranes are indispensable in the construction industry. Additionally, mini cranes are significantly simpler to remove from building sites. As the industry leader in lifting solutions, we constantly strive to offer cranes and machinery that can do unusual tasks. We have completed so many exceptional projects that when paired with our tools and knowledge, we can tackle practically any lifting difficulty. Contact GGR Group by phone or by clicking here if you require specialised equipment and guidance.